A warehouse racking system is fundamental to any distribution, storage or material handling operation. The importance of a well-organized warehouse setup cannot be overstated, especially in today’s fast-paced logistics and distribution environments.

Efficient storage solutions such as selective pallet racking systems play a critical role in minimizing wasted space, streamlining inventory management, and reducing overall operational costs. In the 1900s, many industries began searching for a better, more economical, and simpler way of packaging their products. This brought about the use of cardboard boxes, which were easy to pack, cheap and could be disposed of after use.

The only disadvantage was that the boxes still needed to be moved individually, and if the products were heavy, the boxes could not be that large. This made packaging cheap, but labour became more expensive. And that’s when metal industrial racking systems, like selective racking, became an essential part of warehouse operations.

Selective racking allows businesses to adjust to changing storage requirements without significant overhauls. This adaptability makes it a preferred choice for warehouses experiencing shifts in product volume and types.

Today, storage racking has become an industry of its own, and one of the most common is the selective pallet racking system. Thanks to the eCommerce industry, the shipping business has increased their requirement. Every year, billions of dollars are spent on warehousing, and a large portion of that is allocated to selective racking systems.

With warehouses facing growing demands to meet quicker delivery times and improved product accessibility, selective pallet racking systems are vital to optimizing operations. They provide efficient, accessible storage while maintaining cost-effectiveness and operational flexibility.

The Business Research Company carried out an in-depth investigation of the present and future state of the racking industry. The high need for warehouse space is likely to increase the growth of the pallet racking market. With the increase in online shopping, the desire for warehouses has risen to the point that a huge global strategy and distribution network is needed, further increasing the demand for selective racking systems.

What is Selective Racking?

Selective pallet racking is a storage system used to store items on pallets. The pallets are stacked in rows horizontally and on multiple levels vertically. This increases facility space while simplifying inventory demand. Selective pallet racking, in particular, allows you to choose any pallet load from the system without moving other pallets. This is especially useful for warehouses with high inventory turnover or diverse product lines that require easy access.

What makes selective pallet racking stand out from other types of selective racking systems is its flexibility and accessibility. Because each pallet is individually accessible, selective racking is suitable for businesses that deal with a wide variety of products. The ability to select any pallet without disturbing others greatly enhances operational efficiency, making it an ideal choice for warehouses of all sizes.

Different Types of Selective Pallet Racking

Generally, racking systems are classified into two categories, including:

1. Low-Density Racking Systems

Selective Pallet Racking:

It is highly flexible and works with any type of forklift, so no specialized lift trucks are needed.

2. High-Density Selective Pallet Racking Systems

High-density selective pallet racking systems are an essential group of storage solutions used for warehouse achievement tasks, from those that permit direct access to each pallet.

High-density storage pallet racking systems include:

- Double or triple-depth racks

- Drive-in/drive-through

- Push back

- Pallet flow

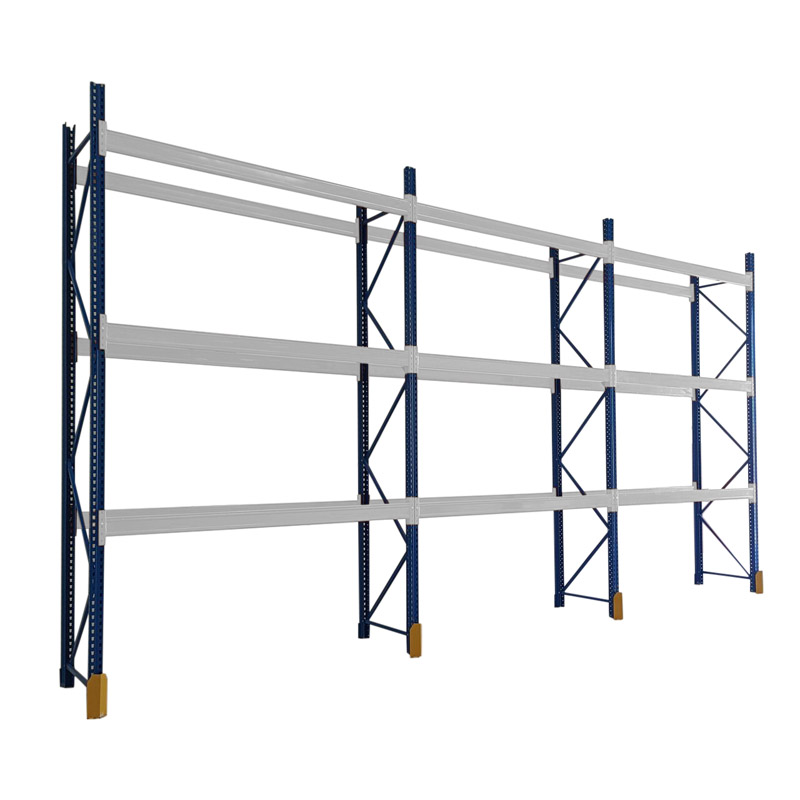

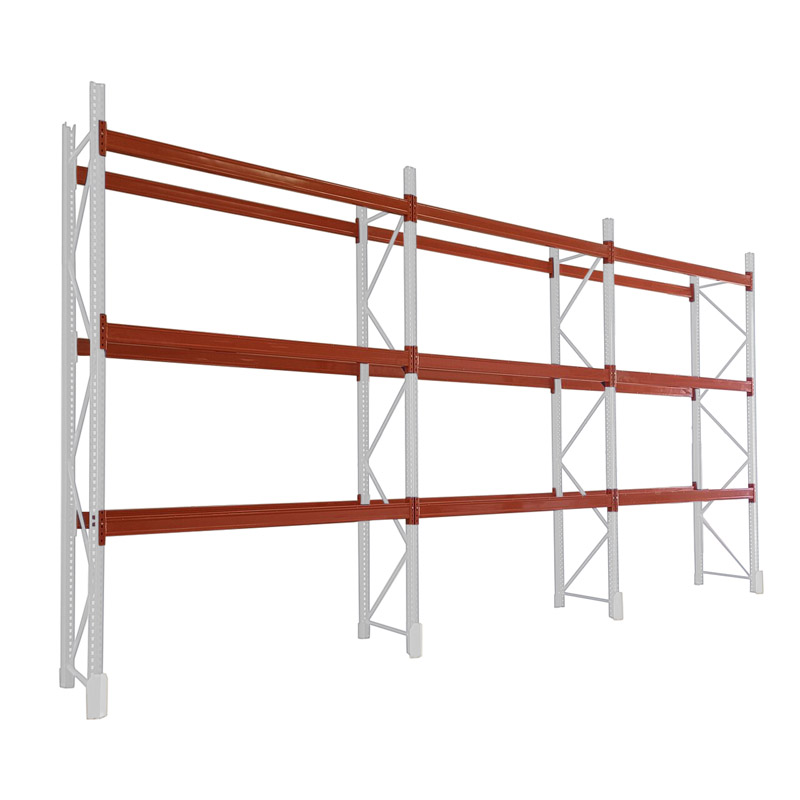

Essential Parts of Selective Pallet Racks

Selective Pallet Racking comprises different parts designed specifically for the loads to be stored. These include:

1. Upright Frames:

It is also known as upright columns. They are the side supports for the structure. These frames are crucial for maintaining the stability and overall integrity of the selective pallet racking system. They ascertain the height and depth of the pallet racking system.

2. Horizontal Beam (Load Beam)

They are heavy-duty rails that connect upright frames and create shelves for storage racking. They provide the surface storage area where loads are placed on a selective pallet rack. Such beams ensure proper weight distribution, supporting heavy loads without compromising safety or functionality.

Selective pallet racking beams are of two basic styles:

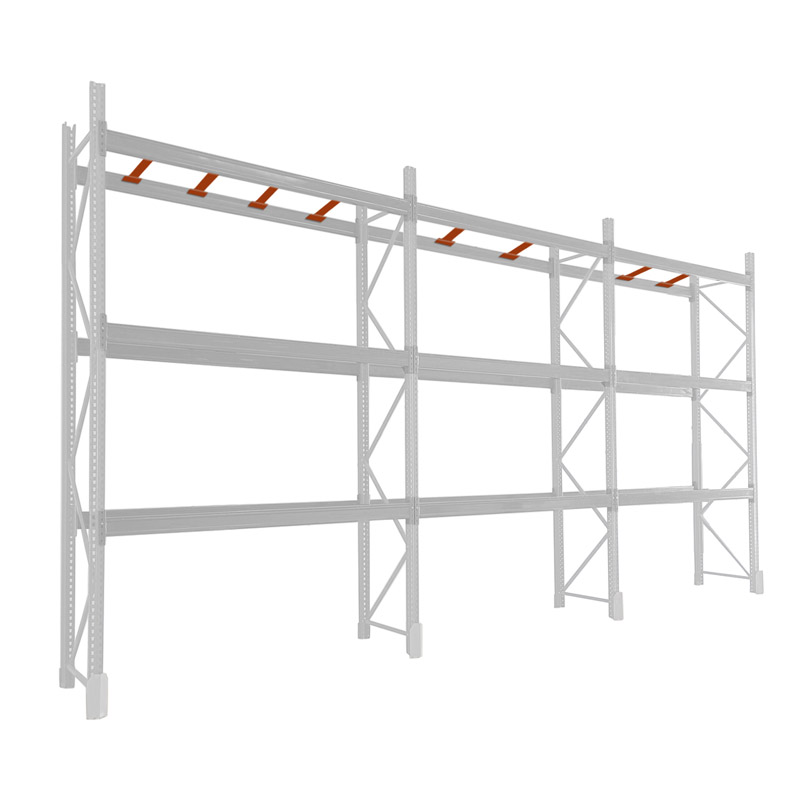

- Step Beams: These feature a lip on the inside of the beam and support cross bars and mesh deck

- Box Beams (Structural Beams): They are suitable with wire mesh and safety bars and do not have an inside lip.

3. Braces

Braces consist of horizontal and diagonal bars. These bars are usually fused to the upright frames. Thus, it supports the frames and provides additional strength to the selective pallet racking systems.

4. Cross Bars

They support selective pallets between two horizontal beams and restrict them from falling through. These bars provide added stability, ensuring the pallets remain secure during storage and handling. In other words, they are called support bars.

5. Clips (Safety Drop Pins, Beam Locks)

They are small fasteners used to hold horizontal beams to upright frames. These clips are vital for enhancing safety and preventing accidental beam displacement. It prevents the beams from accidentally disengaging during loading or unloading.

Baseplates (Foot Plates):

This creates a means of attaching the rack to the floor and as well increases the firmness of the pallet racks.

Benefits of Selective Pallet Racking System

The type of selective warehouse racking system you choose can positively or negatively impact your operations and profits.

1. Makes Use of Vertical Space

Selective racking pallets enable you to use the whole space attainable in your warehouse. They allow you to stack goods higher than just floor level within your facility. The ideal selective racking solution extensively increases the storage capacity of your warehouse when compared to floor stacking.

2. Durability

Durability is crucial, so always look out for systems from reliable and reputed manufacturers. Poorly made columns can disintegrate or damage from crashes or collisions with handling equipment like fork trucks. This can lead to occupational hazards like staff injuries, product damage and more. All these can be avoided by going for the right selective pallet racking system specifically made to meet your facility’s needs.

3. Productivity

With a better-designed selective pallet racking system, you can improve the productivity of your operations. Load and unload products without delay and with less difficulty. In addition to increased efficiency, selective pallet racking reduces the risk of workplace injuries by minimizing manual handling, creating a safer environment for your employees. Time saved from unloading can enable your team to be assigned to other areas of need in the warehouse.

4. Ensures Satisfaction

Smooth order achievements improve the overall customer experience and will help you attract more clients to your industry. Consistent, reliable service builds customer trust and loyalty, ensuring repeat business and positive reviews that can help grow your reputation.

5. Flexibility

There are different types of selective pallet racks. This allows you to make the perfect selective racking choice for your needs.

Selective Pallet Racking for Your Needs

There are crucial factors to consider when choosing the right type of warehouse selective racking system.

1. Budget

Each pallet rack type varies in cost. So, before getting a particular one, you should consider the upfront and long-term maintenance costs. Additionally, factor in installation expenses and the potential for future scalability, which could impact your overall budget in the long run.

2. Floor

Space Also, consider the number of rooms obtainable in your facility. Some selective racking systems take up more space than others. Ensure to choose a system that will suit your facility.

3. Material Handling Equipment

Specialized material handling equipment is needed for some types of selective pallet racking. For example, if you use narrow aisles, you will need a forklift with a small footprint for maximum transportability.

4. Flexibility

Ensure that your racking must be able to contain whatever product you desire to store. Inventory Management. Some pallet racks are better suited for different inventory management systems (First-in, First-Out or Last-In, First-Out methods). However, ensure that your selective pallet racking can accommodate whichever method you use.

Safety Considerations for Selective Pallet Racking

Safety considerations for racking are not just a legal commitment, but also a high priority for industries. To begin with, owners should follow the guidelines of a racking manufacturer. Installation, operation and maintenance processes should align well with the guidelines.

- Choose the type of pallet racking system as per the size, shape and weight of the products to be stored.

- Use racking that is compatible with the material handling equipment used in the warehouse.

- Do not exceed the recommended working load limit of the racking. This may lead to a harmful failure of the selective racking system.

- Execute regular inspections to keep an eye on damage or overloading. Check for any loose component or frame damage that may cause pallets to collapse. This is one of the key factors for a safe warehouse environment.

- Indicate signs of caution if the racking is used as a retail infrastructure. This is important where customer traffic is present.

- Avoid using selective racking systems until they reach the state when they become vulnerable and faulty. This may cause loading and unloading problems.

- Avoid placing pallets on the edge of aisles that act as an obstruction and threat to fatal accidents.

- Perform regular rack audits on with the help of a qualifies inspector. As audits need to be checked considering RMI design and safety standards ensuring 100% safety.

The above-mentioned safety considerations hold good for selective racking systems as well.

How to Determine the Right Selective Pallet Racking System for Your Business

You must consider certain aspects to enable you to choose the right warehouse racking system.

- Amount of storage density needed

- Accessible floor space and building height

- The obtainable inventory method

- The location of doors and columns in the facility

- Inventory rotation

- Load sizes and weights

- The type of pallets and the suitable size.

- How much will new equipment cost, as well as the installation

Working with the right pallet racking system can provide many benefits for your warehouse. Therefore, you should ensure that you choose the right storage racking system to gain maximum benefits and profits.

Count on Us to Get a Custom Warehouse Selective Racking System for Your Business

AL Kheera Steel Works is one of the leading racking and shelving companies in the UAE for racking systems and shelving systems. We empower warehouses with customized selective racking solutions that optimize operations and improve the bottom line.

Whether you are looking for selective pallet racking or any other type of warehouse racking system, we can help you. Contact us to discuss your unique requirements. We will be happy to assist you in making the most of your investment.

Very good article, allow me to refer to and write the source of this article. Thank you!

Thanks, Dang for reading this article. You can refer to and write the source.

Thanks, it is quite informative.

Thanks Gita, we are glad to help you with this post.

Amazing! Its truly amazing post, I have got a much clear idea concerning from this article.

Hey, Emma Thanks a lot for your comment and appreciation.

Thanks for your quick reply. We need a racking system that has high density, should be cost-effective and can store lower turnover inventory with a long shelf life.

The drive-in racking system would be an appropriate option for you. It is the lowest cost and most popular high-density pallet racking system.

You can refer to this drive-in pallet racking system guide for more details.

This guide is very helpful to understand the selective racking system. We have a warehouse that has limited space. And we need a storage solution for similar items. Could you please suggest us an appropriate pallet racking system for this?

Hello Shadab, We are happy to help you. Please give us the details about inventory you need to store, your required storage density, and product shelf life. This detail will help us to suggest you an appropriate pallet racking system.